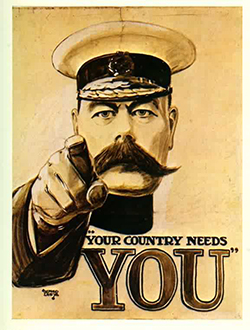

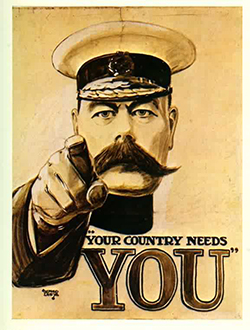

“TO FIGHT FOR AUSTRALIAN MANUFACTURING”

The Society’s guest speaker was Albert Goller the Chairman of META. Albert was the Chairman and Managing Director of Siemens Ltd in Australia and New Zealand from 2002 to 2012 but now leads META, a federally funded organisation whose aim is to combine manufacturing businesses through collaborative projects to create business opportunities on a global level.

Albert gave one of the most passionate and frank presentations on the need to ensure manufacturing continues to thrive and provide a significant proportion of the nation’s economic output. His core message is that after the mining boom must come the manufacturing boom! It is a false assumption to assume that because we are losing the Australian automotive industry we will automatically lose our manufacturing industry but as Albert said it must be a different form of manufacturing, away from the traditional mass production because our cost structures are too high and besides that we do not compete on a level playing field as many countries and governments around the world see the crucial importance of having a thriving manufacturing sector. But to paraphrase Mark Twain; “rumours of manufacturing’s demise are greatly exaggerated” and META are determined to play a key part in ensuring this does not happen. Their main focus is to form a number of manufacturing precincts or clusters for key industry sectors where the businesses who together in a collaborative approach to address new markets and new opportunities looking right across the value chain from design to delivery. However Albert acknowledged, endorsing exactly what Vernier’s recent audit of manufacturing companies including Vernier Member companies themselves concluded, that collaboration is not in Australian companies DNA and so META’s challenge is to change this position.

In the 18 months they have been operating they have formed a database of over 3400 companies including over 40 universities and learning establishments and are now putting together clusters or hubs to look at such new collaborative opportunities as portable housing, carbon fibre, Australian clothing and sports technology, which he pointed out is a $300b industry worldwide. The organisation has a goal of 80 different collaboration hubs over 10 industry sectors. Albert sighted the example of the strength of Germany’s SME’s who have a long history of collaboration far different from Australia, who despite being the 13th largest economy in the world seems to have an adversity to collaborating and not yet quite appreciating we now have to compete in a globalised world.

Under the message of the “Art of Manufacturing” Australian companies now have to use innovation, sustainability, speed and mass customisation to really compete in the intensive world of the future. In the question and answer section after the presentation, Albert was asked about the role of government, and in particular this government, in supporting their cause. This is a particularly pertinent point as META was originally set up under the previous government with a 5 year brief but unfortunately the current government have chose to only fund this extensive program until the end of 2014; although META are now exploring self funding options. In a passionate answer that may have surprised some of the audience, the message it is not going to be achieved by relying on governments of either persuasion, it has to come from those in the industry, and organisations like Vernier, demanding manufacturing is given its rightful place in the economy – manufacturing and its organisations and institutions must become a stronger voice on the political stage. When asked about the hope for areas like Geelong who has lost so many manufacturing jobs recently again Albert’s answer was frank having good news and bad. The bad is that many who have lost their jobs will struggle because the current message is one of retraining but training is currently focused on past skills; the future skills needs have not even yet been identified. But the good news is that the region is already fighting back and there are quite a number of new and innovative projects being developed in the region.

of the “Art of Manufacturing” Australian companies now have to use innovation, sustainability, speed and mass customisation to really compete in the intensive world of the future. In the question and answer section after the presentation, Albert was asked about the role of government, and in particular this government, in supporting their cause. This is a particularly pertinent point as META was originally set up under the previous government with a 5 year brief but unfortunately the current government have chose to only fund this extensive program until the end of 2014; although META are now exploring self funding options. In a passionate answer that may have surprised some of the audience, the message it is not going to be achieved by relying on governments of either persuasion, it has to come from those in the industry, and organisations like Vernier, demanding manufacturing is given its rightful place in the economy – manufacturing and its organisations and institutions must become a stronger voice on the political stage. When asked about the hope for areas like Geelong who has lost so many manufacturing jobs recently again Albert’s answer was frank having good news and bad. The bad is that many who have lost their jobs will struggle because the current message is one of retraining but training is currently focused on past skills; the future skills needs have not even yet been identified. But the good news is that the region is already fighting back and there are quite a number of new and innovative projects being developed in the region.

Overall it was an excellent and what should be a thought provoking message for all who passionately care about manufacturing. So the question for the Vernier members is how we can help because we certainly should!

[fancy_title style=”1″ align=”left” heading_style=”h1″ title_color=”#999″ title_lines_color=”#eee”]Event Details[/fancy_title]

Our speaker for July is Albert Goller from META. July 10th 2014 from 12:30. Kooyong Lawn Tennis Club, 489 Glenferrie Road Kooyong.

META a membership organisation made up of Manufacturers and Researchers who collaborate together to reinvigorate Manufacturing and build an agile, innovative and collaborative manufacturing industry.

Another speaker who is right on message from a Victorian Vernier Society perspective.

Mr Albert Goller is the former Chairman and Managing Director of Siemens Ltd in Australia and New Zealand from 2002 to 2012.

Commencing his career as an electronics engineer with Siemens in Germany in 1973, Albert has held a number of senior executive positions throughout the world including President and CEO of Siemens Canada Ltd in Toronto and Head of the Corporate Office for E-business in Munich, Germany.

He has a Masters Degree in Information and Telecommunications from Paderborn University in Germany and has been nominated as one of Australia’s most influential engineers by Engineers Australia magazine consecutively from 2004 – 2010.

Albert took up the position of Chair of the Australian Government’s Industry Innovation Precinct initiative for Manufacturing last year, and has recently formed the organisation representing the Manufacturing Precinct – called META. Albert is a passionate advocate of manufacturing and is convinced a national approach to Australian manufacturing, through the establishment of META, can generate new thinking and action within the sector.

Best practice in manufacturing principles

Best practice in manufacturing principles

of the “Art of Manufacturing” Australian companies now have to use innovation, sustainability, speed and mass customisation to really compete in the intensive world of the future. In the question and answer section after the presentation, Albert was asked about the role of government, and in particular this government, in supporting their cause. This is a particularly pertinent point as META was originally set up under the previous government with a 5 year brief but unfortunately the current government have chose to only fund this extensive program until the end of 2014; although META are now exploring self funding options. In a passionate answer that may have surprised some of the audience, the message it is not going to be achieved by relying on governments of either persuasion, it has to come from those in the industry, and organisations like Vernier, demanding manufacturing is given its rightful place in the economy – manufacturing and its organisations and institutions must become a stronger voice on the political stage. When asked about the hope for areas like Geelong who has lost so many manufacturing jobs recently again Albert’s answer was frank having good news and bad. The bad is that many who have lost their jobs will struggle because the current message is one of retraining but training is currently focused on past skills; the future skills needs have not even yet been identified. But the good news is that the region is already fighting back and there are quite a number of new and innovative projects being developed in the region.

of the “Art of Manufacturing” Australian companies now have to use innovation, sustainability, speed and mass customisation to really compete in the intensive world of the future. In the question and answer section after the presentation, Albert was asked about the role of government, and in particular this government, in supporting their cause. This is a particularly pertinent point as META was originally set up under the previous government with a 5 year brief but unfortunately the current government have chose to only fund this extensive program until the end of 2014; although META are now exploring self funding options. In a passionate answer that may have surprised some of the audience, the message it is not going to be achieved by relying on governments of either persuasion, it has to come from those in the industry, and organisations like Vernier, demanding manufacturing is given its rightful place in the economy – manufacturing and its organisations and institutions must become a stronger voice on the political stage. When asked about the hope for areas like Geelong who has lost so many manufacturing jobs recently again Albert’s answer was frank having good news and bad. The bad is that many who have lost their jobs will struggle because the current message is one of retraining but training is currently focused on past skills; the future skills needs have not even yet been identified. But the good news is that the region is already fighting back and there are quite a number of new and innovative projects being developed in the region.

How to change a company!

How to change a company!